The following is a glossary of terms commonly used in the woodworking and cabinet making industries. The list is not exhaustive and entire books could be, and probably have been, written on some of the terms. We attempted to keep the descriptions brief, so it can be used as a quick overview. We welcome your suggestions.

General Cabinet Types:

Face Frame Cabinets: The traditional construction method of building cabinets. A flat frame is attached to the front of the cabinet box to conceal the exposed edges of the plywood box sides.

Frameless Cabinets: A cabinet construction method developed in Europe that does not use a face frame. The cabinet doors mount directly onto the cabinet side using concealed hinges.

European cabinets: See Frameless Cabinets.

Cabinet Door Terms

Stile: The vertical member of a door frame

Rail: The horizontal member of a door frame

Framing Stock: The moulded material used for stiles and rails

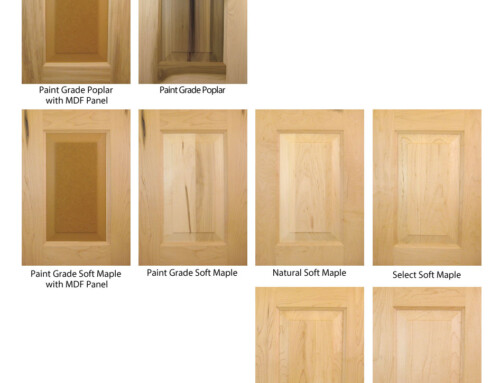

Door Panel: The center panel of a door, can be a solid wood panel or a plywood panel

Insert Panel: Used to describe a door with a plywood center panel

Mortis: The female portion of a mortis and tenon joint

Tenon: The male portion of a mortis and tenon joint

Inside Bead: The moulded profile on the inside of the framing, also called inside profile

Outside Bead: The moulded profile on the inside of the framing. Also called outside profile or edge profile

Groove: The portion of the inside bead that accepts the panel

Panel Lip or Tongue: The thin edge of a raised panel that goes into the groove of the stiles and rails

Quirk: Detail or step when referring to a cabinet door profile or the gap next to a profile bead. An angle or turn when referring to a cabinet.

Blind Mortise and Tenon Miter Joint: A mortise and tenon joint that is totally enclosed and not visible from the exterior of the door

Finger Joint Miter Joint: A joint where male and female fingers are machined on either end of the stiles and rails of a door

Doweled Miter Joint: A joint that is mitered and has dowel holes bored in each end of the stiles and rails and secured with a glued in dowel

Cope and Stick Joint: The traditional joinery method for a cabinet door where mirror image router bits are used to create frame stock profiles that mate together to form a tight joint

Spline Joint: A joint where a mortise is cut in both ends of the stiles and rails and a wood spline is inserted and glued into the mortises to secure the joint.

Coping: The machining of the female end of the door rail which is a mirror image of the sticking profile or inside profile

Sticking: The machining of the inside profile or inside bead on the stiles and rails

Inside Profile: The machined edges on the inside edge of a door. Same as the inside bead

Outside Profile: The machined edges on the outside edge of a door. Same as the outside bead

Panel Profile: The machined edges on the center panel of a door

Applied Molding: A decorative molding that is attached to the face or inside edge of a door

Mullion or Muntin: The cross bars that are installed in an open frame door, that give the door the look of window panes. Can also be the center stile or rail in a multi-panel door

Lites: Panes in a mullion door (also known as French lite door), usually 4, 6 or 9 lites per door

Slab Door: A door that is one solid piece of wood and has no moulded surfaces except an edge profile

Inset or Flush Door: A door that is inset fully into the cabinet opening and does not protrude out from the face frame of the cabinet.

Full Overlay Door: A door that covers almost all of the face frame and gives the look of a European cabinet

Mullion Frame Glass Door: An open frame door that has mullions installed to look like a window.

Open Glass Frame Door: A door that has no center panel. Glass or any other decorative panel can be installed in the opening.

Lazy Susan Doors: Usually a pair of doors that are installed in a corner cabinet and are hinged in the center, between the two doors to allow access to the entire opening

Bar Backs: Refers to the front or ends of a kitchen island that look like a series of doors.

End Panels: Refers to a panel or door unit that covers the exposed end of a cabinet to give it a finished look

Finished Ends: See End Panels

Wainscot Panels: A wide, multi-panel “door” or series of doors that can be used to cover a section of wall or create a seamless look on the back of a kitchen island. These are typically 42” high, have a bottom rail that is taller than the top rail, and are often capped with a chair rail.

Appliance Panels: Panels that match the materials or door styles used in surrounding cabinets and cover the face of refrigerators, freezers, dishwashers and compactors.

5-Piece Drawer Front: A drawer front with two rails, two stiles and a center panel and is constructed like a door

Slab Drawer Front: A drawer front that is made from a solid or glued up piece of wood

Drawer Front or Drawer Face: A slab or 5-piece door that covers the end of a drawer box – typically has horizontal wood grain on the panel (5-piece) or entire slab.

Glued Up Panel: A wood panel that is made by gluing together strips of wood

Machining Terms

Rabbet: A groove cut parallel to, and at the edge of a board

Sticking: The molding operation to machine the inside profile of stiles and rails

Dado: A slot made across the grain

Biscuit Joint: A type of joinery that uses a thin wafer of compressed wood that is inserted and glued into grooves to connect two pieces of wood

Glue Joint: The point where two pieces of wood have been glued together

Flute: A deep round-bottom channel machined into the wood. Typically used on columns and posts as a decorative element.

Thickness Plane or Surface: A machine which reduces the thickness of boards or panels

Dovetail: A fan or dove-tail shaped mortise and tenon joint which interlock together tightly and form a very strong joint. Mainly used in high end drawer box construction

Kerf: The gap that is left when material is removed by a saw blade. The width of the kerf is equal to the thickness of the saw blade

Rip: A saw cut made parallel to the grain of a board

Groove: A slot or channel machined on the edge of a board

Cross Cut: A saw cut made across the grain of a board

Beading: A decorative semicircle-shaped groove cut into the face of a board, leaving what looks like a bead running the length of the board, typically on the inside or outside edge, but also used in the center of two v-grooves creating a “beaded v-groove” pattern.

V-Groove: A decorative v-shaped groove cut into the face of a board

Miter: A joint made by fastening two pieces of wood together that have been cut at a 45 degree angle

Chamfer: A small, angular cut made on the edge of a board, usually at a 45 degree angle

Eased edge: Softened Edge: Usually a small radius cut on the edge of a board

Round Over: Same as and eased edge but with a much larger radius

Bullnose: Same as a round over

Ogee: An elongated and flattened S shape made on the edge of a board

Cove: A concave shape machined on the edge of a board

Lumber Terms

Annual growth rings: The layer of growth to the circumference of a tree in a season. Recognized by different texture from summer and winter

Heartwood: The area in a tree from the center pith extending to the sapwood and is darker in color than the sapwood

Sapwood: The outer area in a tree from the hearwood to the bark, and is lighter in color than the heartwood

Softwood: Lumber from a group of trees with needles or scale-like leaves and has no reference to the hardness of the wood. Many softwoods are actually hard and durable. Pine and cedar are examples of softwoods.

Hardwood: Lumber from a group of trees with broad leaves and has no reference to the hardness of the wood. Oak, cherry, maple, beech and mahogany are examples of hardwoods.

Tiger Stripe: A ribbon-looking grain pattern in wood and is usually running across the grain. This is very prevalent in maple.

Flat Sawn: A method of sawing lumber where parallel cuts are made through the entire log, tangential to the growth rings, also called plain sawn.

Quarter Sawn: Boards which have been cut so the wide surfaces are 90 degrees to the annual rings. This type of cut reduces cupping.

Rift Sawn: Boards are milled perpendicular to log’s growth rings, on an angle between 45° to 75° creating a straight, linear grain pattern.

Long Grain: The grain that runs the length of a board

End Grain: The grain that is on the end of the long grain – the grain at the cut end of a board

Dry Kiln: A heated and humidity-controlled structure in which lumber is dried

Green Wood: Lumber that has just been cut from a log and does not reference the color of the wood

Wood “In the White:” Wood that has no finish or stain applied

Air Dried: Wood that has been allowed to dry without adding any heat to the process

Seasoning: The time it takes wood to dry and usually applies to air drying

Kiln Dried: Wood that has been dried in a kiln with controlled heat and humidity. Hardwood is usually dried to between 6 and 8 percent moisture content.

Sticker Stain: A bluish black stain in lumber caused by trapped moisture under the stacking stick layers used in the air drying process

Mineral stain: A stain in the wood caused by the tree absorbing certain minerals from the soil in which it grew.

Length: A measured dimension that runs with the long grain of a board

Width: A measured dimension that runs across the grain of a board

NHLA Grading Rules: A set of lumber grading rules set by National Hardwood Lumber Association and are the standard rules that apply to the grading of hardwood lumber

FAS: The highest grade in hardwood lumber meaning “Firsts and Seconds”

Select: The grade just under FAS

#1 Common: The grade under Select and must be 66% free of defects

#2 Common: The grade under #1 Common and must be 50% free of defects

Board Foot: A measurement of lumber (width in inches x length in inches divided by 144 x the thicknesss)

Square Foot: Same as board foot but does not account for the thickness, just the surface feet

Linear Foot: A measurement in lumber that pertains only to length

Sanding Terms:

Abrasives: Sanding products used to sand wood and are usually expressed as sheets, belts, wide belts and rolls

Abrasive Grit: The abrasive material that is attached to the surface of sand paper and is expressed by 100 grit, 120 grit, 150 grit, 180 grit, 220 grit, with the lowest number being the coarsest and the highest number being the finest.

Grit sequence: Refers to the sanding grit sequence used on wide belt sanders, for example 120, then 180 then 220.

Cross Grain Scratch: Small scratches made by the abrasive grit that run across the grain of the wood

Open Coat: A grade of sand paper where the abrasive materials are spread out leaving void areas between the grains of the abrasives

Closed Coat: A grade of sand paper where the abrasive materials are tightly packed together leaving no void areas between the grains of the abrasives.

Aluminum Oxide: A man made abrasive widely used in sand paper. It is usually used in more coarse grits.

Silica Carbide: A man made abrasive that is much sharper than aluminum oxide and works best in the finer grits

Sanding Chatter Marks: Evenly spaced marks left by widebelt sanding. Usually caused by an uneven splice where the belt is glued together.

Sander Revolution Marks: See sanding chatter marks

Sanding Dips: A dip on the surface of material that is caused by a hesitation in the stock being run through a wide belt sander

Edge Sanding: A dip on the surface of material that is caused by a hesitation in the stock being run through a wide belt sander

Wide Belt Sanding: A sanding process in which boards are machine sanded through a series of progressively finer grit belts

Orbital Sanding: A sanding process using a hand held sander that rotates in a random orbit. Also called DA sanding.

Veneer: A thin layer of wood that is glued and stacked in layers, to create plywood, or the surface layer of a plywood board, glued to a base of lower grade material.

Plywood Terms:

Rotary Cut Veneer: Veneer that is peeled from a log in a circular motion and produces a more prevalent grain pattern

Plain Sliced Veneer: Veneer that is cut in thin, vertical, parallel pieces from a log and produces a more even grain pattern.

Face Grade: Refers to the grade of the face side of plywood

Back Grade: Refers to the grade of the back side of plywood

Cross Band: The veneer that makes up the core of plywood and the grain direction is perpendicular to the long grain

Core: The material used for the inner area of plywood and is usually expressed as veneer core or mdf core

Veneer Core: Refers to veneer that is used as the core rather than the face or back of the board

MDF Core: Refers to MDF that is used as the core of the board

MDF: Stands for Medium Density Fiberboard. MDF is made from pulverized wood mixed with an adhesive and formed into sheets

Particle Board: Similar to MDF but not as dense. Mainly used for construction purposes.

Lumber Core: Refers to a panel that has veneer on both sides and a solid wood panel as its core

Book Match Veneer: Successive layers of veneer are arranged side by side to resemble a mirror image of each other

Slip Matched Veneer: Successive layers of veneer are arranged side by side with no intended grain matching

Telegraphing: Refers to a defect in plywood caused by a defect or void in the core material and it is seen on (telegraphs through to) the surface of the plywood.

Hardboard: Similar to MDF but is manufactured under higher heat and pressure making it much harder.

Equipment Terms

Router: A machine or hand held tool that uses a small bit, rotating at very high RPM’s.

CNC Router: A large production router that is CNC controlled (computer numerically controlled)

CNC Equipment: Any machinery that employs computer controls

Thickness Planer or Surfacer: A woodworking machine that reduces the thickness of material

Moulder: A woodworking machine that cuts a profile on linear stock

Up-Cut Saw: A saw used to cut stock to length. The saw blade cuts up from the bottom of the material.

Gang Rip Saw: A rip saw with multiple saw blades that can cut boards into several strips in one pass.

Straight Line Rip Saw: A saw used to rip board to width

Optimizing Cut Off Saw: A saw used to cut stock to length and is controlled by a computer to obtain the most yield from a board

Sliding Table Saw: A saw used to cut panel stock to size and has a sliding table

Table Saw: A saw used to cut panel stock to size

Edge Shaper: A machine that cuts a profile on the edges of boards

Shape and Sand Machine: A through feed machine that has multiple shaper cutters as well as edge sanding heads.

Double End Tenoner: A machine that machines both ends of stock in one pass.

Joiner: A machine that trues the edge of boards prior to gluing

Wide Belt Sander: A sanding machine that sands the flat surfaces of material

Radial Arm Saw: A saw used to cut stock to length

Carbide Tipped: A tungsten carbide material used for cutting tools. It remains sharp for a long period of time.

Diamond Tipped: An industrial diamond material used for cutting tools. It gives the best quality of cut and can outlast carbide 10 times.

Mechanical Fasteners: Staples, pins or nails used in woodworking construction

Glue Reel: A revolving clamp used to glue up panel stock

Door Assembly Clamp: A clamp used for cabinet door assembly and is used to hold the joints intact until the glue has cured

Adhesives: Usually refers to glue

PVA Glue: Polyvinyl acetate glue. A commonly used woodworking and craft-making glue.

PUR Glue: Polyurethane glue used in hot melt applications

Stain: A material that contains pigment used to color wood

Dye Stain: A type of stain that dyes the material

NGR Stain: Non-grain raising stain

Wiping Stain: A stain that is wiped on rather than sprayed on

Sealer Coat: The first coat of finish used in the finishing process that seals the wood

Top Coat: The final clear coat in the finishing process. Usually lacquer.

Fish Eye: A defect in the finishing process that causes imperfections that look like fish eyes and is caused by silicone contamination in the wood

Splotching: Caused by uneven absorption of stain in wood with varying density. Very common in cherry and maple

Orange Peel: A finishing defect caused by applying to much finishing material in one coat

White Wood: Wood that has not been finished

Defect Terms

Tear Out: A machining defect that causes a chip out, usually caused by dull tooling or by a swirled grain pattern

Mill Marks or Knife Marks: Marks left by a planer or moulder that give the surface of a board a wavy appearance. If not sanded out, this will cause a serious finishing problem.

Snipe: A dip or gauge on the trailing end of material which has been run through a planer or moulder

Burl: A knotty growth from a tree that usually has a complex grain pattern

Pin Knot: A very small knot, less than the size of a pencil eraser that is the remnant of a small limb

Gum, Pitch or Sap Pocket: A dark discoloration in the wood containing excessive local accumulation of resin or gum. This is very prevalent in Cherry.

Mineral Stain: A dark discoloration in the wood caused by minerals being absorbed into the tree from the soil, very prevalent in hard and soft maple and oak

Mineral Streaks: Dark streaks containing mineral deposits, very prevalent on maples and oaks

Bird Peck: A defect that is actually caused by birds pecking into the tree. It is usually associated with a pitch pocket.

Wane: The edge of a sawn board where the bark or surface of the trunk remains

Knots: Caused by a dead branch that was fully integrated into the tree before it was cut down

Shake: A crack or split in wood caused by damage or drying

Heat Shake: A shake radiating out from the heartwood

Ring Shake: A shake occurring between annual rings

Wind Shake: A separation of the wood at the annual ring caused by the tree being exposed to high winds

Twist: Longitudinal twisting of wood due to uneven seasoning or drying.

Honeycomb: A separation at the annual ring, caused by excessive heat during kiln drying

Season Checks: A defect or separation to the wood at a right angle to the annual ring, caused by uneven seasoning or drying

End Checks: A split or crack at the end of a board caused by rapid loss of moisture during seasoning or drying

Split: A longitudinal separation of the wood along grain layers

Spalting: A change in color, texture or strength caused by a fungus growing within dead wood

Dotty: A soft spongy texture that is the beginning of rot

Warp: Distorted lumber such as twist, cup or bow

Bow: A warp along the length of a board

Raised Grain: The rough condition of sanded wood when the hard, late wood rises above the soft, early wood when moisture is applied

Cup: Transverse bending of a board, can be convex or concave