Read through our Cabinet Doors FAQ to find information on how to order, product and material tips, payment info, shipping information and much more. Please Contact Us if you don’t find the information you’re looking for.

TaylorCraft cabinet door company builds an innovative, proprietary cabinet door style called 4S.

The first doors in our new patent-pending 4S series are 3/4″ Shaker, 1″ Shaker and 1-1/4″ Shaker doors, designed for those looking for a “slim shaker” or “skinny shaker door style” but without the drawbacks of typical slim shaker or skinny shaker construction.

Our 4S doors boast a patent pending construction technique that ensures superior durability and stability over time.

Key features that set the TaylorCraft 4S apart from other doors on the market:

- No lip moulds, no miter joint construction

- True 3/4″ door thickness

- Seamless, smooth, jointless back

- Real wood – in the white

- Works with standard hardware and hinges for 3/4″ thickness doors

- 90 degree joints which create a stable, durable frame

- No nails, nail holes or fasteners that create hinge placement concerns

- True craftsmanship

Crafted to perfection, our 4S doors are truly unique, setting the standard for exceptional quality and innovation.

View 4S cabinet door style options and our 3-D interactive door samples here.

Cabinetmakers, contact TaylorCraft today to begin offering the unmatched quality and craftsmanship of the TaylorCrafted 4S Shaker doors to your customers!

View our 4S – Skinny Shaker – Slim Shaker Hardware Placement Guide.

If you have very short drawer fronts and want a look that is as close to the door profile as possible, you can reduce the rail size to 1-5/8” for our cope and stick doors to reduce overall drawer height or use a slab drawer front with similar outside edge.

Minimum drawer front heights:

6-1/2” with reduced rails and raised panel

5” with reduced rails and flat panel

4” with slab drawer front.

We do not offer prefinished cabinet doors at this time. Our unfinished cabinet doors will arrive to your shop in the white (raw) and ready for finishing, and depending on the material and humidity, after being given a light, touch up sanding.

The cabinet door styles shown online are only a fraction of the design possibilities available from TaylorCraft Cabinet Door Company. You can mix and match our inside edge, outside edge, applied molding and panel profiles to create your own unique cabinet door designs. We stock 18 wood material options and offer other readily available wood species upon request.

Call us for more information on placing a custom cabinet door order.

We manufacture to exact sizes. Because wood is a natural product that expands and contracts as the environment changes, at time of delivery we allow for +/- 1/16″ of the requested dimension.

Doors taller than 48” will automatically be split into two equal panels unless otherwise requested. The maximum recommended height and width can be exceeded however these products are not guaranteed against warping or twisting. For maximum guaranteed height and width please see our door specification guide.

At 48″ height and 24″ width we recommend splitting cabinet doors into two panels divided by a center rail or stile to prevent warpage and twisting.

Doors taller than 48″ will automatically be split into two equal panels unless otherwise requested.

Our wholesale cabinet doors are priced per square foot to 1/16”. Total square footage is calculated by multiplying the door width x height and then dividing by 144.

TaylorCraft’s cope and stick cabinet door and edgebanded cabinet door thickness is 3/4”.

We don’t offer different cabinet door/drawer front thicknesses at this time.

Due to the custom nature of our cabinet doors and our very quick lead times, door orders go into production very shortly after the order is received. Therefore we will not be able to change an order once it has been placed into our system and approved for production.

TaylorCraft Cabinet Door Company is a wholesale supplier which means we sell our cabinet doors and provide pricing only to verified cabinetmaking and woodworking companies. If you are a homeowner or hobbyist, you are welcome to purchase our products through a reputable cabinetmaking business in your area.

Simply call our Customer Success department or complete the Contact form found online and we will be happy to answer any questions and set up your account. To process a quote we need company name, contact name, phone number and shipping address. To place an order into production we need to have the payment method established and either a credit account opened or one-time or recurring payment authorized via credit card or ACH from a bank account. Customers may download a Credit Application or Payment Authorization from our website or request a copy from our Customer Success team. It can be emailed, mailed or faxed back to us.

Please note, TaylorCraft Cabinet Door Company is a wholesale supplier and sells only to verified, cabinet industry trade professionals. We do not sell to the general public.

Our minimum cabinet door / 5 piece drawer front order is 1.5 square feet. Minimum slab drawer front order is 1 square foot

Our in-the-white, or unfinished cabinet doors are finish sanded before shipping. You may need to give the doors a light touch up sand before staining depending on the amount of time and humidity exposure between shipment and staining.

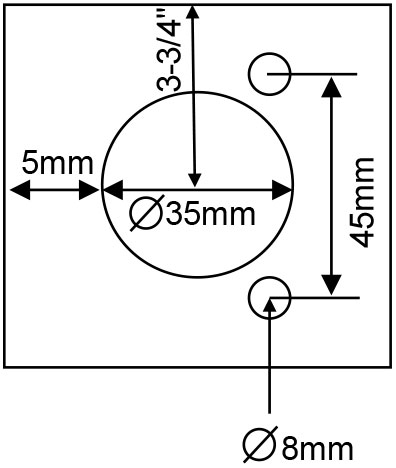

Boring for European Hinges

To order doors bored for hinges check “Bore L (left) or Bore R (right) on your order form, next to each door that you want bored. Specify left or right bore as viewed from the front of the door. For bottom hinge bore write “bore bottom” in notes section of order form. Standard bore pattern includes center cup and dowels. For cup only (no dowel holes) specify “cup only” in notes. Standard lead time applies.

Standard placement is shown below. Call for information on special hinge bore placement.

Bore hole is 3-3/4” on center from top of the top rail edge and bottom of the bottom rail edge to the center of the bore hole.

Hinge boring is not available with OEABD outside edge.

THIS BORE PATTERN DOES NOT WORK FOR ALL HINGE TYPES. Check your hinge manufacturer for their required bore setting. TaylorCraft sells Blum® Clip Top 120° European Hinges (71T5580) and hinge plates (175L6630) which work with our boring pattern shown above. Screws are not included.

Special Considerations:

- Doors taller than 45” ordered bored for hinges will automatically receive 3 hinge bores unless otherwise requested.

- Doors taller than 55” ordered bored for hinges will automatically receive 4 hinge bores unless otherwise requested.

- Doors taller than 65” ordered bored for hinges will automatically receive 5 hinge bores unless otherwise requested.

- Doors and drawer fronts ordered outside of size recommendations become the sole responsibility of the customer.

TaylorCraft Cabinet Door Company is located in the small but beautiful city of Taylor, Texas just outside Austin. View more information on why it makes sense to be a central Texas cabinet door manufacturer.

If you’re thinking about stopping in for a visit you should know that some of the best barbecue in the state can be found just down the street in Taylor at Louis Mueller Barbecue. Some of the best fried green tomato sandwiches and the best apple pie we’ve ever tried can be found at the Texan Cafe and Pie Shop and some of the best beef fajita tacos are served up at El Corral Lozano on 2nd Street, so when you are in town, make time to stop for lunch!

Before you stop in, be sure to make an appointment so we are prepared to give you the best service possible.

To make an appointment call 512-352-6355. We look forward to serving you! We are a to-the-cabinetmaking-trade, wholesale only cabinet door supplier so our appointments are reserved for verified cabinetmakers.

If you are a homeowner, please ask your cabinetmaker to specify TaylorCraft Cabinet Door Company doors, so your cabinets are built with high quality, custom cabinet doors made 100% in Texas, USA.

Our Customer Success team is available to take your call during the following normal business hours (except during holiday closures):

7:00 am to 3:30 pm Central time Monday through Thursday

7:00am to 2:30pm Central time Friday

You may fax or email your order to us any time. Orders received before 10 am Monday through Friday will be processed that day. Orders received after 10 am will be processed the following day. All orders must be approved before being placed into production. Our fax number is 512-853-4077.

We accept company check, Visa, MasterCard, American Express, check by fax, EFT or cash. If you set up a credit line with TaylorCraft, payment is due within 15 days of invoice unless other credit agreements have been approved . If you do not set up a credit account, payment must be received by TaylorCraft at time your order is placed into production.

If you are paying by credit card, your card will be charged when the order is placed into production.

Delivery method depends on order size and location. We use shipping companies with the best reputation in each geographical area. Please inspect the packaging for every job you receive and if there is ANY damage to the package, even minor damage, tears, water marks, etc., always note the damage in writing on the delivery receipt, even if you think the product is ok. Please use specific details noting location and exactly what the damage is. Specific notation helps expedite the claims process if there is ever an instance where product is damaged, and it will encourage shippers to handle products with the utmost care.

The way a product is packaged is not only important for damage prevention in transit, but the packing material itself and the process of unwrapping is part of the user experience.

We have worked to engineer and re-engineer our packaging based on feedback from shipping experts and our experience shipping thousands of doors throughout the United States.

So what did we learn about shipping cabinet doors and components that might be useful to you and how do we package our cabinet doors?

- Cabinet doors should be fully wrapped so they are protected from sunlight and excessive exposure to humidity changes. If you leave the doors in our packaging, laid on a flat surface, until you are ready to finish them, air/humidity exposure is minimal, there is no exposure to light so the doors won’t end up discolored and the doors will stay flat, as opposed to leaning them up against the wall which can cause bowing/warpage.

- Too much packaging material, wrapping the doors in cardboard a few at a time and shipping them separately on a big job, takes extra time to open, creates a mess in the shop and produces a lot of waste.

- At TaylorCraft, shipments of all but small orders are sent flat packed, no more than 36″ high on pallets, making them easy to offload and store. Doors are placed face to face, separated by foam sheets for protection. Customers can stack the used shipping pallets and sell them to companies who pay to pick them up. Our doors are packaged by job, when possible.

- When doors rub against each other, it polishes or scratches the surface – both scenarios cause finishing problems. Our packaging ensures doors have almost zero room to move, which prevents damage to the surface your customers will be scrutinizing.

- TaylorCraft’s packaging can save time and money. Many of our customers use the cardboard and foam from our packaging to wrap their cabinets and protect them in transit to the jobsite, recycling the material multiple times or even stack the cardboard and sell it to a recycler. We love to hear this! Every possible part of our packaging material is made from post-consumer recycled products.

- A dependable carrier is key! We partner with known, dependable carriers, and ship our products nationally.

We’ve done a lot of research but by no means have we stopped analyzing and improving our shipping and packaging. We welcome your comments and feedback!

While we use the most reputable carriers in each geographic area for our shipments, damage in shipment can occur. Please inspect the packaging for every job you receive and if there is ANY damage to the package, even minor damage, tears, water marks, etc., always note the damage in writing on the delivery receipt, even if you think the product is ok. Use specific details noting location and exactly what the damage is. Specific notation helps expedite the claims process if there is ever an instance where product is damaged, and it will encourage shippers to handle products with the utmost care.

We do offer 1 day and 3 day expedited (rush) lead times for one to three pieces. For over 3 pieces we offer 3 day expedited lead times. Call for 512-352-6355 for more information on getting your order into the system as soon as possible and for special needs outside these parameters.

No. We do not ship our doors outside the United States.

Our products are available for shipment throughout the United States. We do not sell or ship products internationally.

TaylorCraft offers a proprietary, patent-pending construction, 4S cabinet door that ensures superior durability and stability over time. The first cabinet doors in our new 4S series are 3/4″, 1″ and 1-1/4″ frame width Shaker doors, designed for those looking for a “slim shaker” or “skinny shaker” door style.

Here are the key features that set the TaylorCrafted 4S apart from other doors on the market:

- Not just another mitered, L mould door

- True 3/4″ door thickness

- Seamless, smooth, jointless back

- Real wood – in the white

- Works with standard hardware and hinges for 3/4″ thickness doors

- 90 degree joints which create a more stable, durable frame

- No nails, nail holes or fasteners that create hinge placement concerns

- True craftsmanship

View our interactive, 3-D Rift White Oak and Hard Maple, Select samples

We offer a wide selection of applied moldings that can be added to the inside edge of the door frame. We have streamlined our product offering and are not currently offering mitered cabinet doors. Visit the applied molding door section of our website or view our applied molding profile web page.

We do offer mullion or divided lite (also known as French lite) cabinet doors with a variety of mullion profile and configuration options. We do not provide glass inserts for mullion doors or doors cut for glass.

The wood species shown in our catalog and price list and on our website are just small portion of the materials we use. Call us for information on the specific wood species needed for your cabinet doors. Materials shown in our price list are the materials available within our standard lead times. Call us for lead times and pricing on wood species/materials not listed.

View our wood Materials page for photos and descriptions of our standard wood species and material grades.

We do not offer dovetail drawer boxes at this time. Our focus is making exceptional-quality, custom cabinet doors and drawer fronts. You can count on TaylorCraft Cabinet Door Company for excellent cabinet doors and drawer fronts – it’s what we do, and we do it well!

Cherry changes color as it ages and with exposure to light so extra care must be taken to set the right expectations on color and to make sure it does not darken unevenly due to uneven exposure to light. We do have a list of tips to avoid common mistakes that can be both costly and time consuming when working with cherry wood. View our Tips on Working with Cherry Wood below for details.

When working with cherry wood, be careful to store the components and lumber completely covered until ready to finish, and be careful even after finishing.

Cherry wood continues to darken over time and will darken unevenly if exposed unevenly to sunlight.

This is less pronounced when darker finishes are applied but still good to be careful.

Below is an example of a cherry door that had a drawer front laying across the door face. The partially covered door was exposed to sunlight for half a day and you can see the pronounced darkening of the exposed wood. This dark wood can’t easily be sanded off.

This same result occurs when labels are used on components, leaving a light spot when the label is removed. We recommend keeping cabinet doors packaged until ready to finish. TaylorCraft Cabinet Door Compay’s packaging is designed to protect the door from damage in transit as well as the elements, including humidity and sunlight.

When you are finishing cabinet doors, be careful not to let sweat from your forehead drop onto the door and be careful touching the door if your hands are very sweaty. Oil from your forehead or hands can show up as spots in the finished product.

At this time we do not build doors using customer-provided material.

We have a full online gallery of cabinet door photos showcasing many of our available cabinet door designs, as well as kitchen photographs, bathroom photographs, office and study photographs and media cabinet and entertainment center photographs showing our custom cabinet doors installed. We also showcase contemporary cabinetry and contemporary cabinet door styles in our Contemporary gallery.

See our list of Cabinet Door Storage and Handling Tips to prevent warpage, spots and common cabinet door quality issues.

Book matched veneer is veneer that is sliced and then every other “leaf” of the veneer is turned over like the pages of a book facing each other. The grain figures always match at the joints creating a pleasing look of continuity and symmetry in a bank of cabinets or drawers. See a photo of book matched (side to side) and bank matched (top to bottom: drawer front grain is matched to doors below) veneer doors and drawer fronts on our veneer products page and in our kitchen cabinet photo gallery.

View TaylorCraft cabinet door company’s veneer cabinet doors and drawer fronts and veneer edgeband thickness options.

Read Woodworking Network’s article called “6 Things to Learn About Book Matched Veneer” for additional information.

Yes. you can find an excellent woodworking terms glossary on TaylorCraft’s Blog.

Click this Woodworking Terms link to learn more about common and surprisingly interesting woodworking terminology.

Protecting the environment is very important to TaylorCraft. In order to do our part in minimizing our environmental footprint, we have invested in state-of-the-art machinery that reduces wood waste and saves energy. We have engineered our packaging for minimal use of material while still providing our doors with maximum protection. Our packing cardboard is made using post-consumer recycled material and we encourage recycling our packaging materials after receipt of shipment. We offer sustainable wood species such as European Beech and our wood scraps are recycled and reused by other companies.

We partner with wood suppliers who use forest management best practices as well as sustainable forest management to ensure sustainable future growth and supply and ensure overall health of the forest for future generations.

We are always looking for ways to reduce waste, reuse materials, recycle products and protect the environment and have and will continue to make changes to our processes to reflect these values.