Customized Lumber Grades Produce Greater Cabinet Door Yield

As we talked about in our previous blog, TaylorCraft Cabinet Door Company’s lumber supplier is located onsite, creating the ability to give immediate feedback on lumber deliveries and fine tune lumber grades. Over the years we have developed proprietary grades of lumber specific to our company, our products and our customers’ needs.

Below, industry veteran and lumber yield guru Gene Wengert discusses the benefits of working closely with your wood supplier to customize lumber grades to best suit your needs. There is a definite time and cost savings in the form of improved yield and reduced wood waste!

Heide Osborn

Modern technology and improved customer communication helps lumber supplier better meet manufacturers’ lumber needs.

by Gene Wengert as featured on CabinetMaker+FDM website

New custom lumber programs are helping manufacturers to better match their lumber supply to their actual needs and reduce waste.

One of the modern changes that we all can embrace is the idea that a lumber supplier can work closely with a wood products manufacturing firm to assure that the lumber sold and purchased is exactly what the buyer needed. That is, the lumber grade, size and other important characteristics can provide the manufacturer with optimal productivity, minimal waste, optimal handling and minimum overall cost. In the past, that might have been just a dream, but that day may be here.

The Dream

Here is the hypothesis: Current hardwood lumber grades of the cabinet and furniture industry (FAS, Select, No.1 Common and No.2 Common) do not always precisely (the key here is precisely) depict the true value or needs of a particular company’s manufacturing process and quality standards. That is, the current grades can be fine-tuned or enhanced to improve quality, productivity and profitability (in fact, the NHLA has encouraged the fine tuning of their standard grade rules).

This enhancement would be customized for each manufacturer, as every company is different, so each company has slightly different needs. Further, within the grades, other lumber characteristics can be specified that will, for a specific cabinet, furniture or other manufacturing company, enhance manufacturing. Of course, the needs of a particular company will vary from time to time as their products and manufacturing processes change, so, we need these customized grades to offer appropriate flexibility for individual companies and from company to company.

Wouldn’t that be nice?

To illustrate: Wouldn’t it be nice if a cabinet company running 3-inch-wide rips for mouldings received a load of lumber that was all 96-inch lengths (no shorts), free of all knots (except pin knots), and free of any end splits (end splits alone can cause 2- to 4-percent loss of wood during initial processing, let alone subsequent product defects)? In addition, all lumber in the load would produce two or three ripped 3-inch pieces with essentially no wasteful edging strips; that is, lumber widths would be 6-3/4 inches to 7-1/2 inches and 9-3/4 inches to 10-1/2 inches throughout the load.

Wouldn’t it be nice if a furniture manufacturer could purchase a bundle of lumber that was guaranteed to “fill the bill,” that is, provide the needed number of parts of a required size and color (versus the old system of trying to figure out the footage and appropriate grade mix, plus a little extra, just in case, and not being able to specify the precise color, and so on?

Can dreams come true?

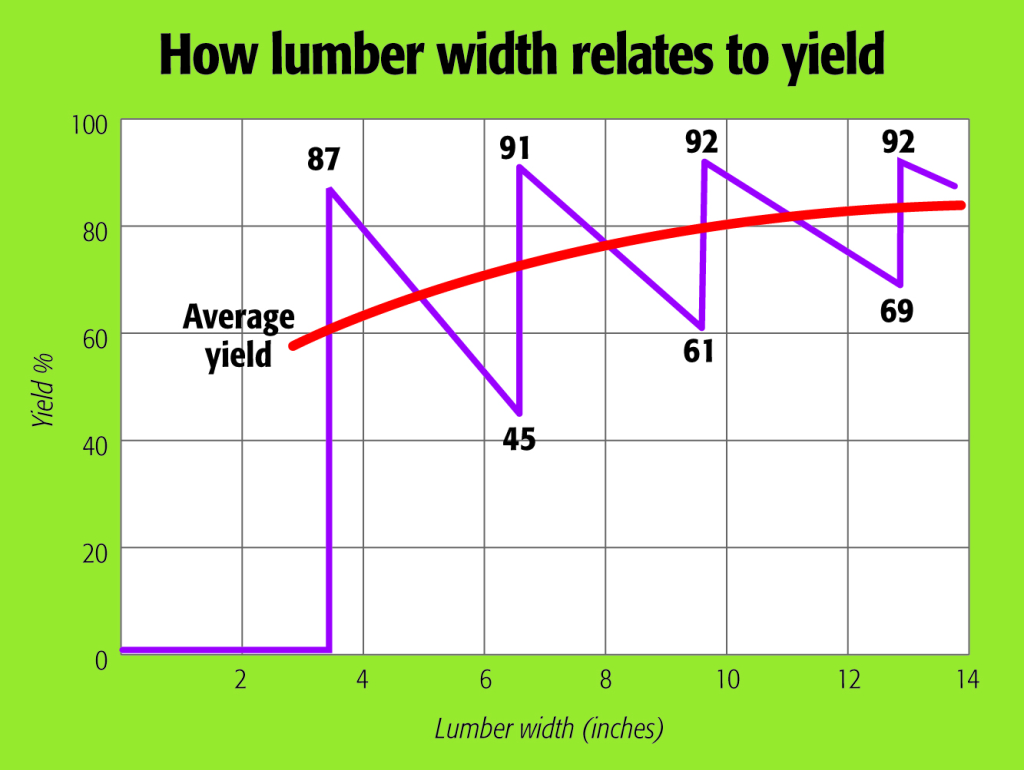

This chart shows how changes in lumber width can have a significant effect on lumber yield.

We need to appreciate that the wood in a cabinet or a piece of furniture is often 75 percent of the total manufacturing cost. This means that any wood waste is very expensive. Increases in yield and decreases in required production processes greatly affect profitability. Further, the time and effort invested in processing wood that cannot be used (the part is too narrow, has a defect, or is the wrong color) is expensive. To address these issues, developers in our industry have been researching how to better adapt and use technology to maximize our wood resources. As computers have been more widely adapted in the wood industry, and as lumber scanners have been developed, we now have the ability to “look” at a piece of lumber and judge its value for a specific manufacturer and for a specific application. I found one article written 25 years ago that suggested this approach. Since that time, there have been many subsequent developments in this processing arena.

Fast forward to today. No longer are lumber yield and processing efficiency a matter of good luck. They are now controllable, based on practical and proven science and technology, leavened with common sense, communication and experience. At least one lumber supply company that I know of is now subscribing to the idea that selling lumber is more than just delivery of so many board feet of a specified grade.

By approaching the sale of hardwood lumber as a service more so than as the sale of a product, Baillie Lumber Company has addressed these changing needs within our industry. We were pleased to see that they have chosen to offer what they call a “Custom Lumber Solution” and since its focus is on results, they want you to receive a test shipment (with no long term program obligation) to see how it will work in your environment and on your products.

Five-step process

The Baillie idea is a five-step process: First, Baillie experts visit your company and conduct a review of your finished products and your manufacturing process–cutting, waste, production rates, and so on. Next, combining their experience, expertise and inventory knowledge, with your specific needs, they develop a customized lumber supply solution, incorporating lumber quality characteristics including grade, color, width, integrity and so on. “The proof is in the pudding,” as they say, so the next step in the process is to conduct a test on a sample of this “new” lumber. Then, both Baillie’s and your company’s personnel analyze the performance and results, looking for benefits and any possible further improvements. If your company is excited about the improvements, then Baillie will continue with communication and updates, as desired or required.

So, how well does this concept work? For one company, they provided specific widths of lumber, cutting the amount of unusable ripped pieces in half. For a cabinet maker that wanted uniform maple color, Baillie’s pre-selection of lumber allowed for 3- to 5-percent more useable surface area on each piece of lumber. A Custom Lumber Solution for a cherry user increased the yield of acceptable parts by nearly 10 percent.

Overall, the idea has been under development for years by many people within our industry, but Baillie is the first that I know of who has made the idea practical and has successfully put it to work. Baillie and perhaps others to follow are helping manufacturers become higher quality, lower cost and more efficient producers to compete for the future in the marketplace. They are to be applauded for devising a better way to utilize materials to beat the competition across town or around the world. Check it out at www.baillie.com/custom and see if you agree.

Gene Wengert